Okay, so if you’ve been in the soap making groups on Facebook lately, you’ve seen all of the transparent soaps that makers have been posting! Quite impressive! I’ve made transparent soap before, but nothing as clear as what we’ve been seeing lately.

So, I got experimenting! I was inspired by a post in our soapmaking group, Saponification Nation, by Harriet Pretzsch. She generously shared her procedure for making a cold process transparent soap. You can find it on her blog here. You’ll have to translate it or join our FB group and search her name…you’ll find it translated.

WARNING! This is an advanced tutorial. You should have some batches of cold process or hot process soap under your belt. If you are new to soapmaking, check out our Free Basic Cold Process Soap Making Guide. Wear safety gear when working with sodium hydroxide and make this soap in a well-ventilated area, especially when working with the lye solution and alcohol.

We now offer an eClass on this quick method! If you want to see it done in videos, sign up here! I’ve updated my process, created new recipes and added some design tutorials. I hope you’ll join us!

Transparent soap is all about the oils that you select and your solvents.

Oils – You want to choose oils that are high in stearic acid and that have a low amount of unsaponifiables that can cloud your clear soap. You want to choose oils that are not yellow or green tinted…Harriet uses tallow, coconut, castor and rice bran. Because you do add lots of solvents (some with water), you want to use a high amount of hard oils to create a hard bar. I would shoot for 60%+ of tallow, lard, stearic acid or palm oil. I tried a few different blends. The more solvents I used, the more stearic acid/coconut oil I used.

Superfat – Because superfat (unsaponified oils) can cloud transparent soap, go with a 0% superfat. We do add glycerin, and that acts as a superfat in your soap.

Solvents

Solvents are what make the magic happen. They dissolve the soap crystals that normally form when combining sodium hydroxide with fatty acids (base oils). Solvents include alcohol, liquid glycerin and sugar. You can use one, or for best results, try a combination.

Alcohol – You can use either isopropyl or ethyl (ethanol) alcohol. Ethanol seems to create a more clear soap. Each type of alcohol comes in different strengths. You want to find the purest/highest strength that you can so that you’ll end up with less water in your soap.

- Isopropyl – Isopropyl is also commonly called rubbing alcohol. It comes in different strengths, from 50%, 70% and 90%. Like I said, isopropyl doesn’t seem to be the best in transparent soap but it is cheaper than ethyl and does work. Use the highest strength that you can find.

- Ethyl (Ethanol) – This type is best for transparent soap, but it is also more expensive. Denatured alcohol is a type of alcohol that you can find at the hardware store. It has a poison added so that people don’t drink it. You can use denatured alcohol in transparent soap. Everclear (from the liquor store) is another type of ethyl alcohol. Look for 190 proof (95% alcohol) for best results.

Liquid Glycerin (not glycerin soap!) – This is a great solvent to use in transparent soap. Glycerin is a humectant and moisturizer for the skin. And like I mentioned above, since we use a 0% superfat, glycerin acts as a superfat.

Sugar – Sugar is a simple solvent that you can try in your transparent soap. You’ll need to make a solution before you add it to your soap. Each solution in each recipe makes more sugar solution than needed, so you’ll have a bit left over. Make sure the sugar is completely dissolved before adding the solution to your soap. White cane sugar and beet sugar work best. I tried raw sugar and brown sugar but it tinted the soap a bit. You can also try xylitol. I make a sugar solution using 1 part water to 2 parts sugar. You’ll need to heat it to a boil to make sure all of the sugar melts. As soon as it boils, stop heating or you might burn your sugar.

Storing your soap

Because this soap contains a high amount of sugar and glycerin, it is best if stored wrapped in plastic wrap or shrink wrap. If you don’t, your soap can sweat and even grow crystals. Glycerin likes to draw moisture from the air into the soap and can create a sweaty mess.

Process

Here is how I made each soap. In the past, I’ve always used the hot process method for making transparent soap. I’ve since found out that you can use a quick and hot method that works perfectly! I use this method when making liquid soap paste and dual lye shave soap. No cooking necessary! This process uses high heat to force saponification. I guess we can call it cold process since no heat is added. I sometimes call it quick hot process. 🙂

Step 1: Create a sugar solution. Combine water and sugar and heat just until it boils. Remove from heat and see if it is clear. It usually is clear as soon as it boils. If it isn’t clear, boil a few seconds longer. Do not let it boil for long or it will burn and discolor your soap. Set aside.

Step 2: Measure all base oils (including stearic acid) into a container and melt. I figured heat would help things along so I heated to around 180-200 degrees Fahrenheit.

Step 3: I weighed the glycerin and alcohol into a cup and set aside.

Step 4: Once my oils were melted I created the lye solution. I wanted it to be nice and hot. To make a lye solution weigh the water and sodium hydroxide into two separate containers. Pour the lye into the water and stir.

Safety! Be sure to wear goggles and gloves and mix your lye solution in a well-ventilated area.

As soon as the solution cleared up a bit, I poured it into the melted oils.

Step 5: I used a stick blender to mix. If your formula contains stearic acid, it will get quite thick.

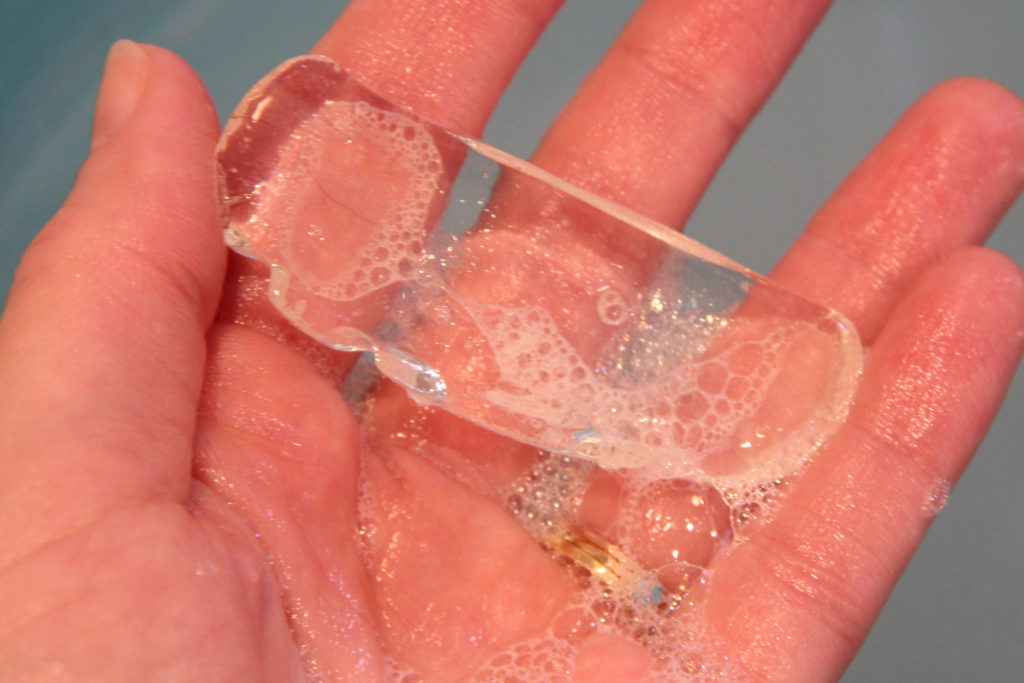

Step 6: Pour in the glycerin/alcohol mixture and blend using a stick blender. Your soap will turn liquidy and soon clear.

NOTE: If you’re making a batch of high-solvent content, add half, blend until clear and then add the rest. (Do this for batch 5 & 6.) If you add all the solvents up front, it takes awhile to come together.

Step 7: Mix for about 2-4 minutes. Stop mixing and see if a skin forms. If a skin forms, pour in your sugar solution.

Step 8: Mix a bit more. I mixed only about 20 seconds more.

Step 9: Pour into your mold and put into the freezer until firm. As soon as the soap is firm, you can unmold it.

Step 10: Wrap it up!

Test batches

Here are some of my test batches that I made and results.

Batch #1

This is where I started. I didn’t have a good alcohol, only 70% isopropyl so didn’t expect super clear soap. I wanted to try it without a sugar solution.

Base Oils

- Stearic Acid – 70 grams

- Coconut Oil – 30 grams

Lye Solution

- Sodium Hydroxide – 15.3 grams

- Water – 30 grams

Solvents

- Glycerin – 30 grams

- 70% Isopropyl Alcohol – 150 grams

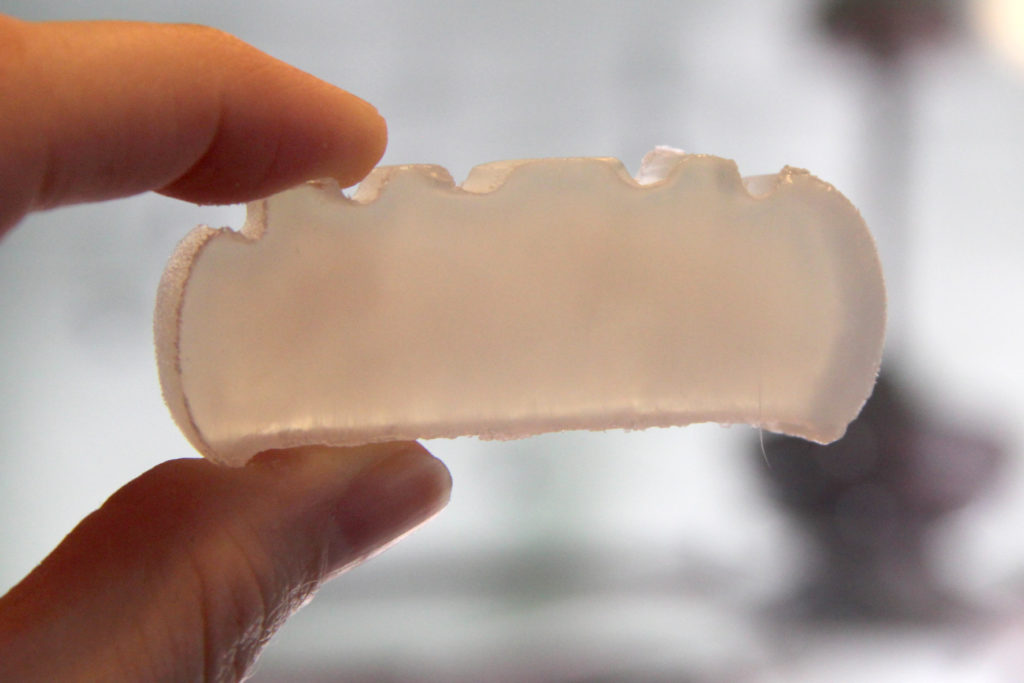

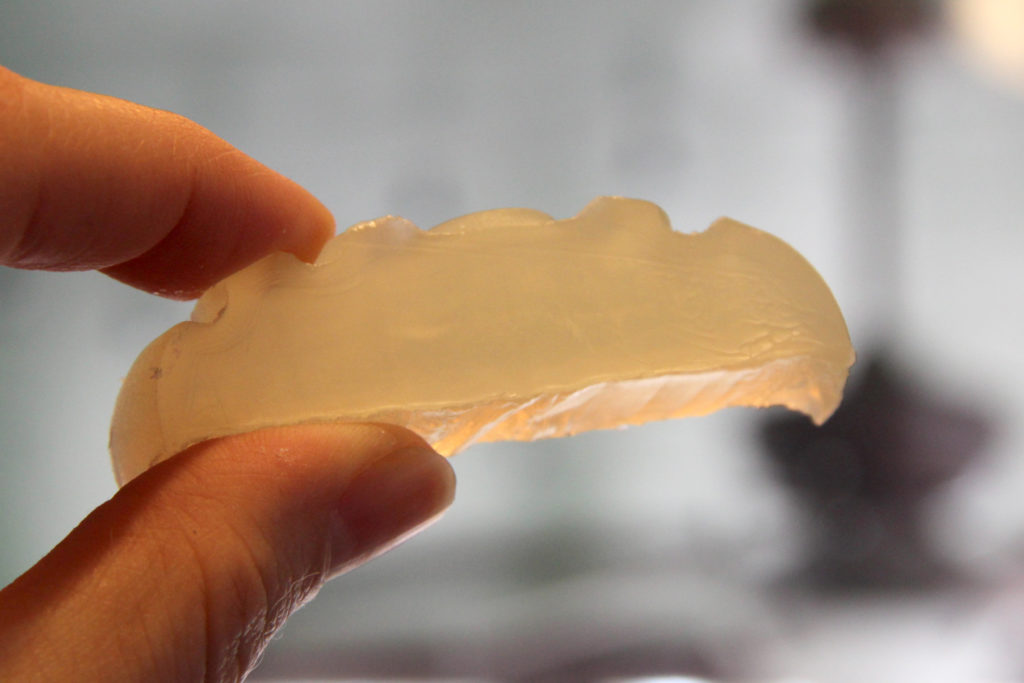

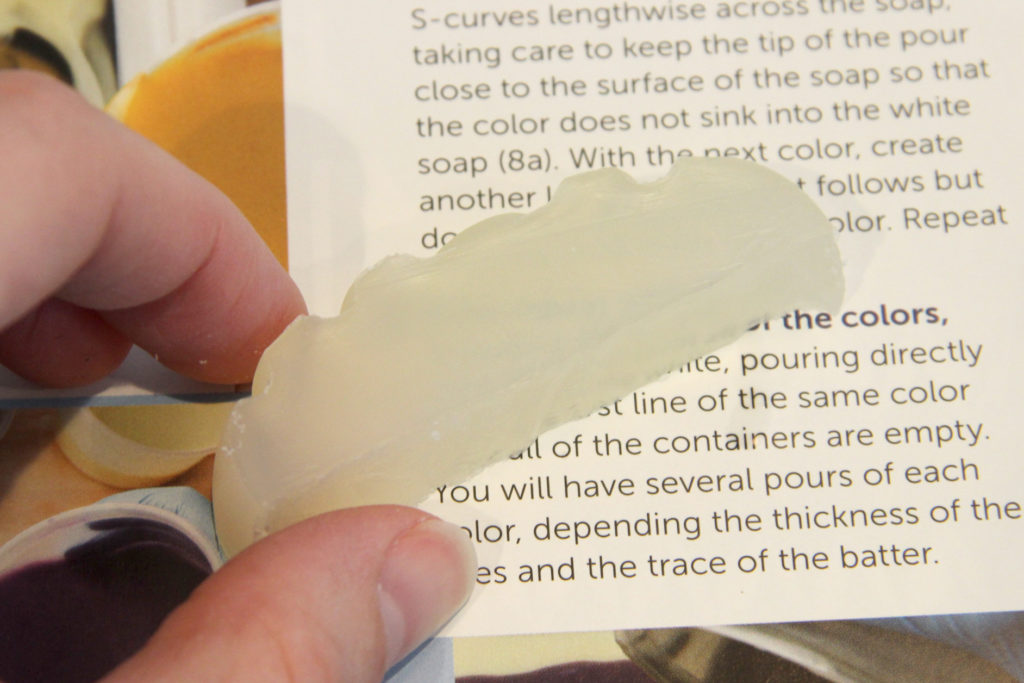

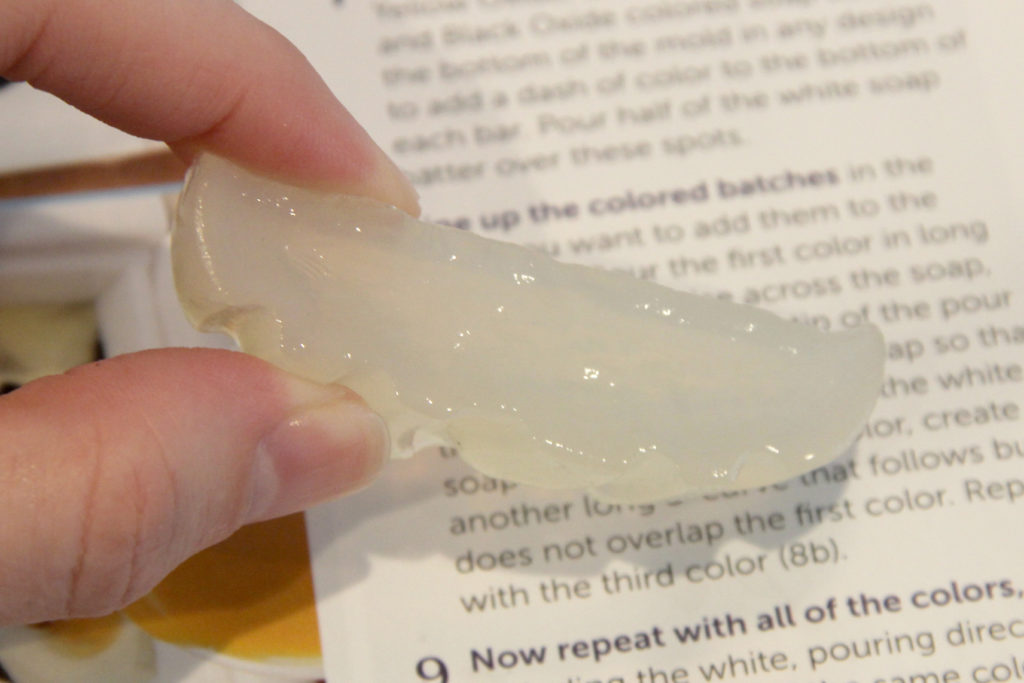

Results: Decent lather, though not very clear. More white than yellow.

Batch #2

This is the same as batch #1, but I did add sugar solution. I used raw sugar, which definitely tints it more yellow compared to regular white sugar.

Base Oils

- Stearic Acid – 70 grams

- Coconut Oil – 30 grams

Lye Solution

- Sodium Hydroxide – 15.3 grams

- Water – 30 grams

Solvents

- Glycerin – 30 grams

- 70% Isopropyl Alcohol – 150 grams

- Sugar Solution – 70 grams (solution was 70 grams sugar + 35 grams water)

Results: Yellow tinted because of raw sugar. Not very clear. More dense lather.

Batch #3

For batch #3 I walked up to the liquor store and bought some Everclear. I bumped up the glycerin and the sugar solution. I started using white sugar at this point.

Base Oils

- Stearic Acid – 70 grams

- Coconut Oil – 30 grams

Lye Solution

- Sodium Hydroxide – 15.3 grams

- Water – 30 grams

Solvents

- Glycerin – 50 grams

- Everclear – 150 grams

- Sugar Solution – 100 grams (solution was 100 grams sugar + 50 grams water)

Results: Decent lather. More clear than batch #1 and 2. Because of the high stearic, this one was a bit draggy to use and tightening to the skin. It will probably improve. But I wouldn’t make this one again…

Batch #4

Batch #4 I went in a totally different direction with different oils, more closely mimicking Harriet’s recipe that she shared. I did use more sugar solution.

Base Oils

- Stearic Acid – 30 grams

- Coconut Oil – 40 grams

- Castor Oil – 20 grams

- Rice Bran Oil – 10 grams

Lye Solution

- Sodium Hydroxide – 15.4 grams

- Water – 30 grams

Solvents

- Glycerin – 30 grams

- Everclear – 70 grams

- Sugar Solution – 100 grams (solution was 100 grams sugar + 50 grams water)

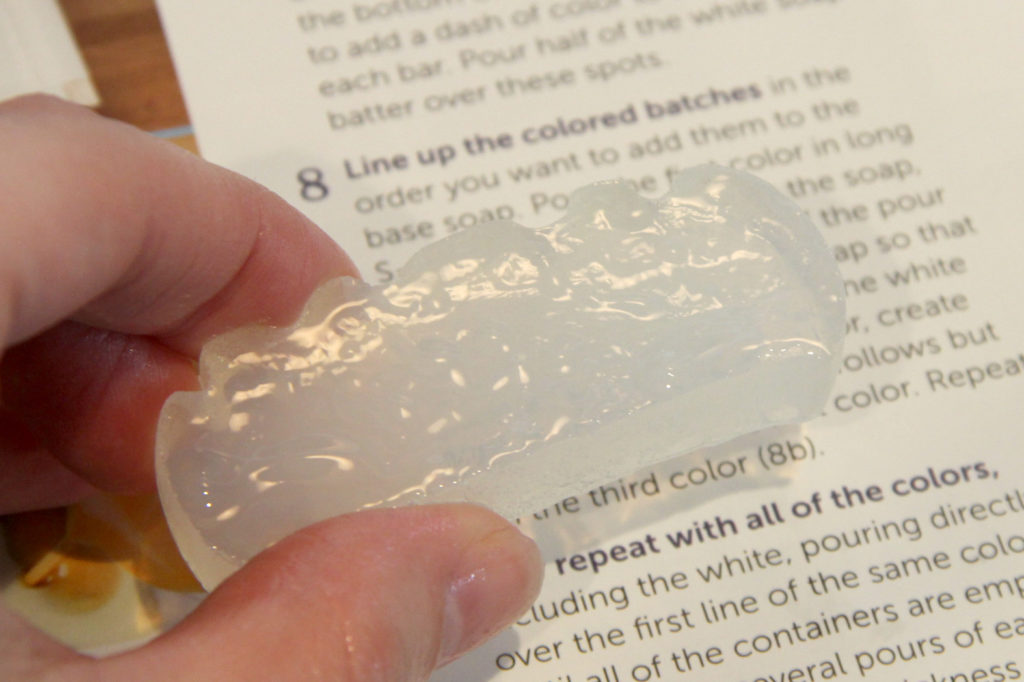

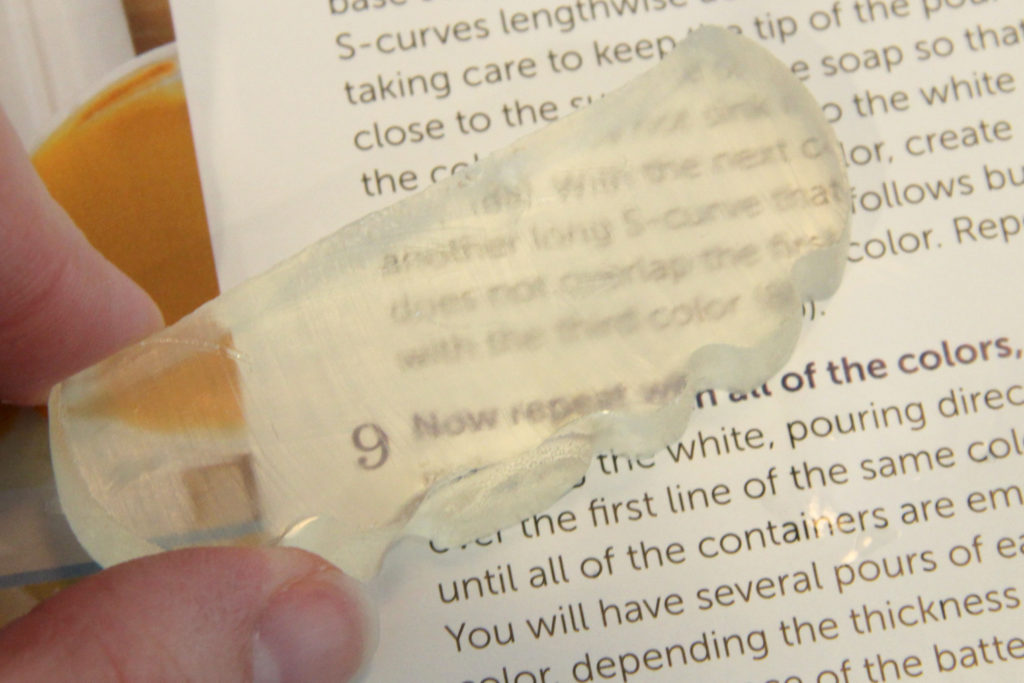

Results: This is a more yellow-tinted soap because of the rice bran oil. Nice lather. This one felt the best once rinsed-off. No tight feeling on skin. I have to say that this is my favorite…even if it isn’t crystal clear. I might try this one again and bump up the solvents.

At this point, I’m not really getting the crystal clear results that I’m looking for. So, let’s bump up the solvents!

Batch #5

For batch #5 I bumped up the solvents quite a bit! I also reversed my stearic and coconut amounts, using more coconut than stearic. Let’s see what happens.

Base Oils

- Stearic Acid – 30 grams

- Coconut Oil – 70 grams

Lye Solution

- Sodium Hydroxide – 17 grams

- Water – 34 grams

Solvents

- Glycerin – 200 grams

- Everclear – 100 grams

- Sugar Solution – 200 grams (solution was 200 grams sugar + 100 grams water)

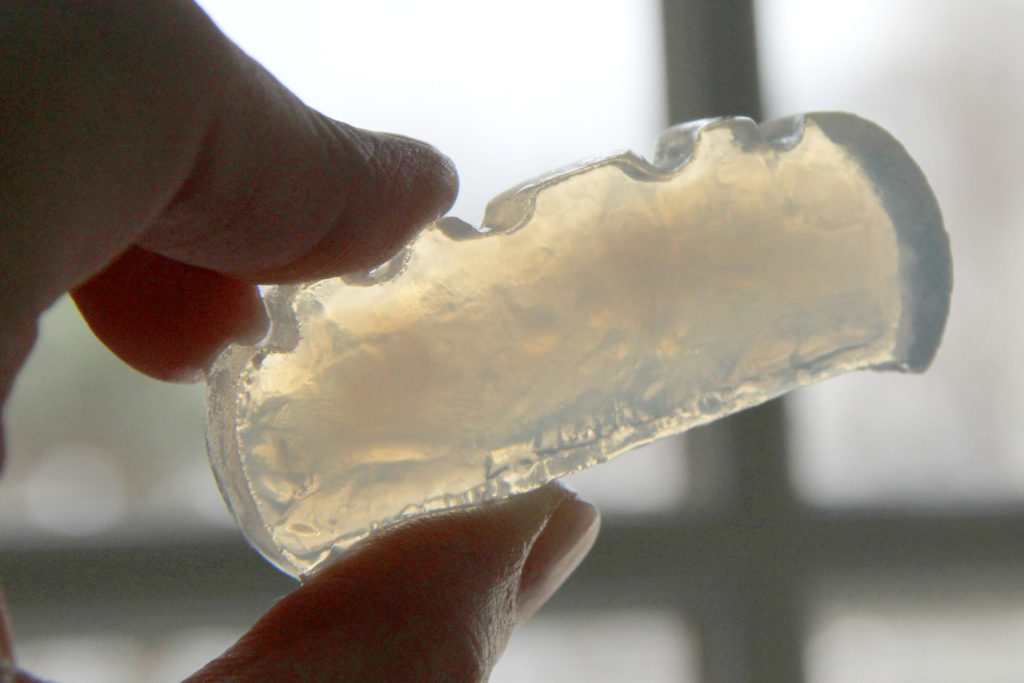

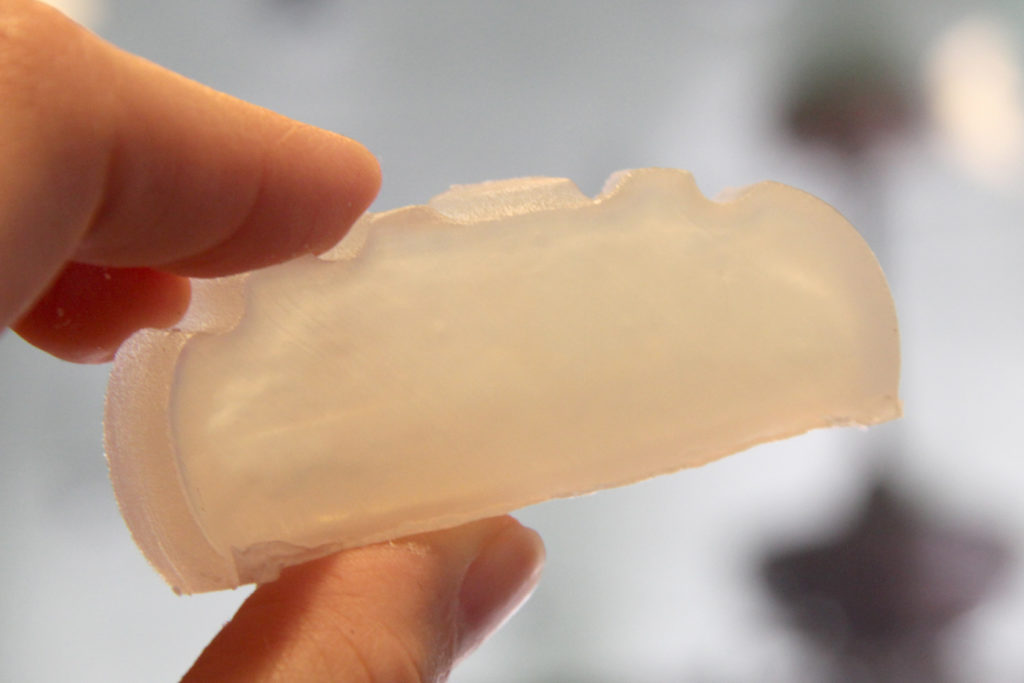

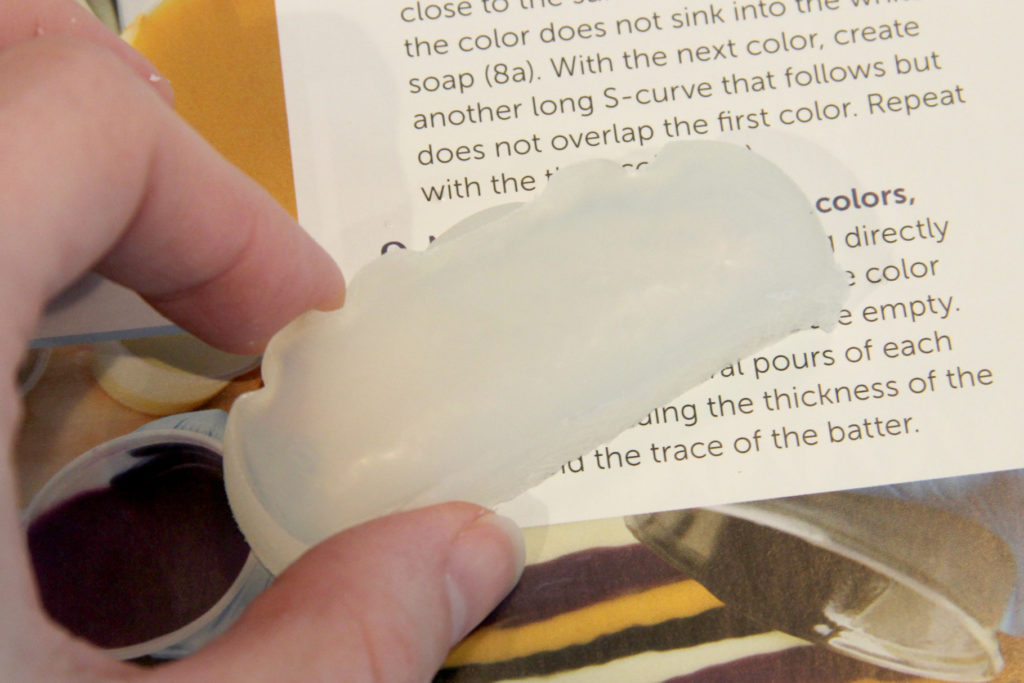

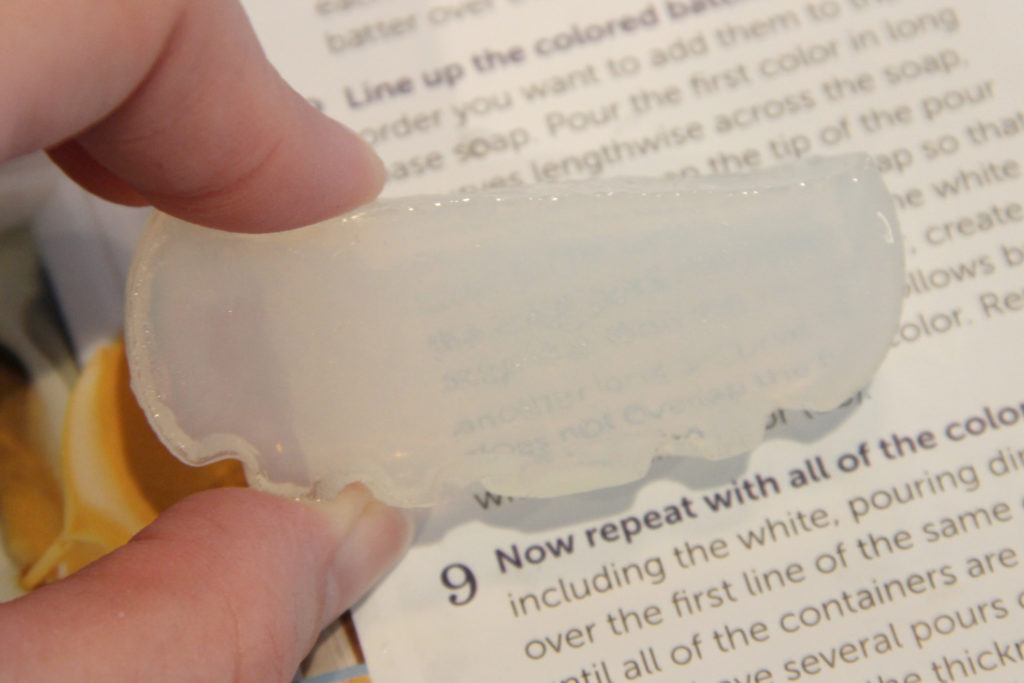

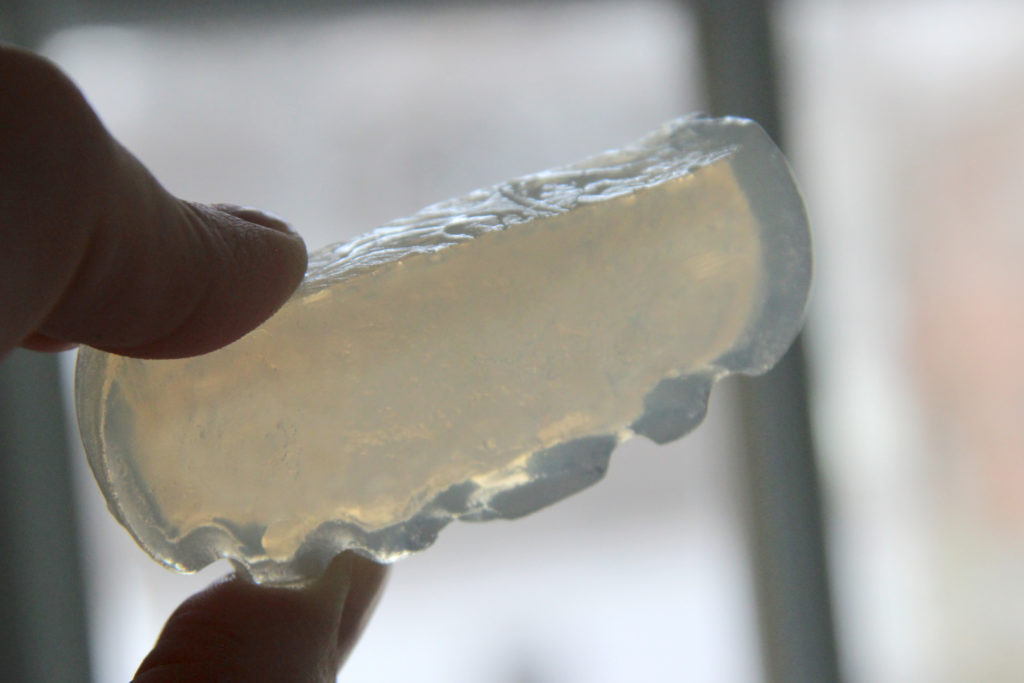

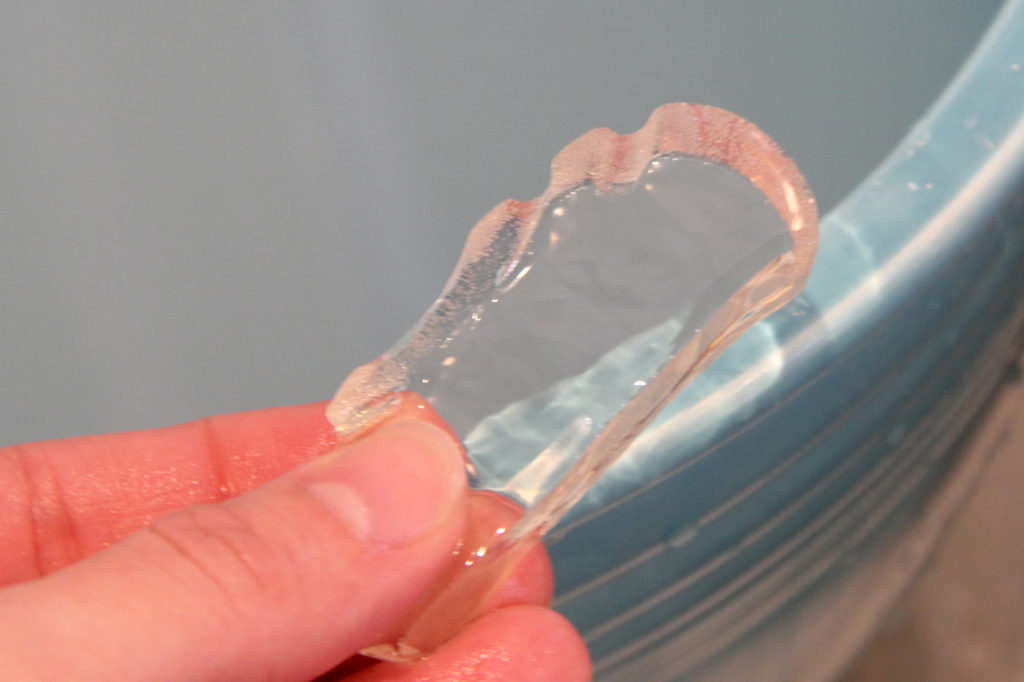

Results: The most crystal clear soap. Must wrap right after unmolding because of the high amount of solvents. Not the best lather when unmolded but it will probably improve a bit.

Batch #6

For batch #6 I wanted to leave out the sugar solution and just use alcohol and glycerin. I bumped up the alcohol a bit.

Base Oils

- Stearic Acid – 30 grams

- Coconut Oil – 70 grams

Lye Solution

- Sodium Hydroxide – 17 grams

- Water – 34 grams

Solvents

- Glycerin – 200 grams

- Everclear – 150 grams

Results: Not as clear as batch #5 with sugar solution. The sugar certainly does help with clarity. Not bad, though. Low lather.

There are my results and recipes that I’ve tried so far. As the soap cures a bit, the lather and clarity can improve. So, test your soap right after you make it and test it again in a few weeks.

Be sure to wrap your soap up or it will sweat…especially batches 5 and 6, that use a higher amount of solvents.

Moving forward! At this point, you can keep pushing the solvents to get clearer and clearer results. You can experiment with different oils. There is a give and take. The more solvents you use, the more clear the soap, but the more issues you might have with sweating, crystals growing and lather. Don’t be afraid to experiment as I did! This process is super quick, so you can knock out several small batches in one day.

Good luck and happy quick transparent soapmaking!

-Amanda Aaron

Hi Amanda! Thank you for the recipes, you are so kind to share them. I need to make a no sweat, white base m&p soap. Can I use the arrowroot and the sugar solvent only? (no alcohols nor gliceryne?) Thanks again!

My soap melted after I took it out of the freezer and wrapped it. They turned into globs inside the saran wrap. I’ve never had that happen before. I’m going to try to heat it up in my crock pot a bit longer and re-batch it, but any suggestions as to why this happened? I used method number 5. Only mistake that happened was my emulsifier died while mixing and I had to hand mix, so I don’t think I was able to mix everything, even though I waited for the film to appear on the surface.

Thank you for this! It worked perfectly well for me. ( I prepared the fourth version)

Hi, I’m wondering how you got the color, as in the hearts you used as an example? Mica, or some other means?

Thanks! Love your posts!!

Hi anyone

Does anyone know how to get rid of the white spots of Streric acid in the clear glycerine soap. Anyone pls help

Hai amanda, thank you for your recipe ???? .. Do you hane any tips for make non sweating glycerin soap ? Or i just need to decrease the water ? Thank you

Thank you for sharing details of all your experiments! This is one of the best tutorials I’ve seen so far. And no crockpot needed either! I’m curious as to how a 100% coconut oil base with 50% glycerin added as the only additive would work. I’m not concerned about high lather or transparency. I am keen on something that can be melted down easily. Have you perhaps tried something like this? Or any idea how it might behave?

Hi Amanda, once prepared is the soap ready to use or needs to cure for some time like the standard cold process soap?

Hi I am also wondering how long it takes to cure this soap and if after curing it resolves the sweating.

Thank you so much for sharing this recipe!

Informative article!! very useful

What should be PH of finished Product ?

7 to 8 ph

Sorry, a ‘brand’ name, not bran. I’ve been working on a few recipes in which I’m using rice ‘bran’ oil so (out of habit) I typed ‘bran’ instead of brand (lol)–ooops, my bad.

Hi! Can I use a metallic mold (alumium) for this kind of soap? Thank you

Realice la formula 4 cambiando algunos aceites solo aceite de coco, acido estearico y aceite de coco y cuando incorporo la legia a los aceites se torna la pasta color de rosa, alguien sabe por que puede suceder?

Your guidance is very clear and easy ingredients given for like me curious and exited but soap maker.thank you so much ☺️.

Does adding more alcohol affect de ph of de lye?. Can only alcohol or any of those solvents work singlehandedly?.

Amander thanks a lot u are really helpful to me. Can methanol be used as everclear, can colour be added

Methanol is carcinogenic please don’t use

Hi. Can sodium lactate or a salt solution be used for additional hardness if you’re running low on hard oils?

Hello, do any of these recipes make true soap (as determined by the FDA) as in “composed mainly of the “alkali salts of fatty acids,” that is, the material you get when you combine fats or oils with an alkali, such as lye.”

I… suppose, as in all of those recipes “fats or oils” are combined with “an alkali, such as lye”.

Hi

Is this a melt and pour glycerine base

Hi Amanda,

Thanks for the detailed explanation and experimentation… very useful. Just wanted to know if this soap is ready to use or it has to go through the curing period of 4 weeks.

Thanks

Hi Amanda. I gave it a try, I used myristic acid instead of coconut oil. It looks pretty clear. I am worried about the ph. I got a 10. Should I let it sit for some days…

Can titanium dioxide be added for a white bar of soap? Also, to produce a goat milk glycerin soap..can goat milk be substituted for some or all water in recipe?

HELP!!!!!!!!!!!!!

I tried your recipe but with castor oil and coconut oil instead of stearic + coconut as per Formula 5 – and it will. Not. Harden. Three days in the fridge and it is still liquid soap!!! I added FO to some of the batches, all stayed liquid. The only one to solidify into a tacky, rubbery bar is the one without FO’s, and completely NOT transparent. My question is: Can I rebatch these? Add them to HP and hope for the best? I really don’t want to throw out a good 15 lbs. of soap!!!! I would SO APPRECIATE an answer!

Castor is a really soft oil and doesn’t really get hard. I would try it with stearic as written. Stearic gives it hardness.

The soaps are looking so wonderful!!! I am a beginner and would want to have you post all these and more to my email. I really want to know about transparent soaps both bar and liquid. Thanks

Hi Amanda,

Does this act like melt and pour? Can we remelt it afterwards?

Thanks for this post. It helps a lot!

Hello! you can remelt it once or twice before it starts to cloud up a bit. 🙂

Thanks so much for the response!

Hi Amanda, I have a question: when you write “Sugar Solution – 100 grams (solution was 100 grams sugar + 50 grams water)” what do you mean?

Do you add 100 grams of sugar solution (made with 100 grams sugar + 50 grams water, so you discard 50 grams of this solution) or you add 150 grams of sugar solution (that is 100 of sugar + 50 grams of water)?

Hi Roberta! Make a solution using 100 grams of sugar and 50 grams of water. When adding it to your soap, only add 100 grams. I always make extra in case water evaporates. I’d rather have more than not enough. Good luck!

Hi

Is this a melt and pour glycerine base

Hi Amanda, may l ask, what is “ever clear”?

Thank you.

Hi Amanda,

Thanks for sharing your knowledge.

I made #5 formulation yesterday, but I didn’t think the freezer part be important, so I put it in the room temperature that was a little warm.

No, my soap turns clear but, brown tint.

What should I do?

I am looking forward to hearing from you.

Best wishes.

Hi Amanda, can a cold lye be used, candy one oil be use, can I use palm oil in adity WT another oil, can salt be use to harden it

Giota, Everclear is Grain alcohol

Giota, Everclear is a ‘bran name’ for one of the (or maybe even ‘the’) highest proof grain alcohol. Typical vodca is 80 proof (40% alcohol per volume). Everclear can be purchased at a whoping 190 proof….so, 95% alcohol per volume. Everclear with a proof of 120 or 151 (60% / 75.5%) is also available but the higher the proof, from what I understand, the better the clairity of the finished product. I looked into Everclear and it’s very expensive, just as I had firgured. I don’t live where moonshine is legally produced else I’d do me some trading (lol) soap for moonshine. Mind you, the legal stuff isn’t called ‘moonshine’ (I don’t think); that name is reserved for the illegal stuff that’s produced without a license.

Sorry, a ‘brand’ name, not bran. I’ve been working on a few recipes in which I’m using rice ‘bran’ oil so (out of habit) I typed ‘bran’ instead of brand (lol)–ooops, my bad.

Hi Amanda, I’d like to try this but can only get my hands on 151 proof Everclear. Do you think that will be okay to use? Thanks, Claudia

You could try it! It might not be as clear.

Hi Amanda, can a cold lye be used, candy one oil be use, can I use palm oil in adity WT another oil, can salt be use to harden it

Everclear, vodka, are essentially ethanol and water. 100 proof = 50% ethanol, 150 = 75% ethanol, 190 proof = 95% ethanol. So if you would use 10g of Everclear 190 proof, that’s 9.5g of ethanol. To get that much ethanol with Everclear 150 proof, you would need 12.7g.

I really love your post u have just educated me, though I haven’t tried it but I trust I will soon. Pls can it be used for commercial batch

I could only get 100 proof vodka and it works surprisingly well

I’m curious about using the 100 proof vodka. How much would you use? Is it the same Amt that the recipe calls for? Do I still need to add 90% alcohol or use one over the other for this recipe?

You will need to cut down on the water for the lye solution because the vodka has more water in it than everclear so I think I had figured that you need to use 45% less water to get it evened out but when you mix the lye solution with the oils then they do trace quicker and the soap will be harder so the melting down process of it after you add the solvents is going to be longer. I had made a really big batch and used different oils when I used the vodka and it is not extremely clear but I have noticed if you melt it down again then it helps to become more clear. I really hope this helps.

Hola este jabon se debe dejar curar? A los cuantos días se puede usar?

Gracias por compartir tanto

Hi Amanda… I’m from Nigeria. Is it possible the formula cones in percentages

Super interesting, thank you for posting. And thank for directing up to Harriet Pretzsch’s site – very cool! I have a question about the superfat issue. I’ve tried using the detergent free version of M&P soap, and it is still really drying to the skin, so I’ve been planning to make something like this for a while. I’m not that concerned about it being very clear, so I assume that means using more glycerine to get a more moisturizing soap. I’ll experiment. But do you have any idea about the finished level of superfat we’re talking about here? Also, I’d rather not use the freezer > what effect do you think putting it in the freezer adds?

Hello! You could actually superfat it with oils, if you’re not concerned about the clearness. Maybe try a 2-3% superfat. Glycerin acts as a superfat as well, not sure the exact amount. I mean you could add up all the amounts and convert into a percentage, but not sure that really means anything. I have heard (and read in prior transparent soap books) that the faster you cool it down, the more clear the soap. I haven’t done a side-by-side to see if that is really true! 🙂

Thanks Amanda.

I want to try it with myristic acid instead of stearic. What do you think?

What is the everclear solvent? ethanol?

Thanks

You could give it a try! Everclear is an alcohol that you drink. It is 95% ethanol.

Sorry to be fussy but don’t drink Everclear straight! People mix it with syrups or fruit juices to mak liqueurs or flavored vodka. The reason it’s more expensive than denatured alcohol (and the reason you buy it in the liquor store) is that liquor taxes are imposed… since you can’t drink denatured to get buzzed, no liquor tax.

Thanks for sharing Amanda. You are the best!

Very interesting read. Tx for info. Going to try this for sure