Module 08 / Lesson 02 (This is an excerpt from our new online business and marketing eCourse, Soap. Brand. Launch. To get more lessons like this, sign up!)

What are Economies of Scale?

In order to know the space, supplies and equipment needed to make your business go according to your intentions, you must have a firm understanding of a common industry term, economy of scale.

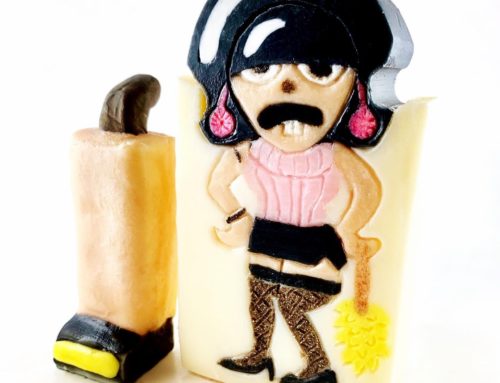

Potentially, the most complex of all commercial enterprises—producing (manufacturing) high-end products—starts with raw materials that may have a very different value in and of themselves. Most consumers do not realize the raw materials it requires to make soap and skin care products. Often, many of the raw materials utilized in soap and skin care production are most-utilized in the food industry. But in our industry, through innovation and organized assembly, these same raw materials are transformed into works of art that happen to be tremendously beneficial to the skin.

As mentioned, starting a soap and skin care business involves a substantial commitment. Often, producing these products calls for a heavy up-front financial investment for specialized equipment and raw materials. This isn’t to say that you can’t start from your kitchen and work your way up, as that is what many do. But as you read further, you will realize the need for more space, better equipment and an exceedingly organized approach to production to get your costs low enough to compete in the larger marketplace. Can this be done in your home? Certainly. I’m not ruling out the ingenuity I’ve seen time and time again from the wonderful folks in our industry.

Furthermore, the necessary space, supplies equipment needed to make your business run is completely and totally your necessity and no one else’s. Remember, the success you are seeking—and subsequent space, supplies and equipment needed—is based on your intentions and goals for your business. If that means a home-based, online retail approach, so be it. If that means a factory, cool. Whatever your intentions, understand that your economies of scale have nothing to do with some industry “standard.” The standard to go off of is created by your intentions and goals.

Economies of Scale

As artisan crafters, we must create as high a quality of products possible at the lowest feasible cost. The simplest method to reducing cost is by raising our economies of scale.

Economies of scale is the cost advantage that arises with increased output of a product.

Economies of scale arise because of the inverse relationship between the quantity produced and per-unit fixed costs. In other words, the greater the quantity of a good produced, the lower the per-unit fixed cost, as these costs are spread out over a larger number of units.

You have experienced this form of economies of scale many times in your life and business. It is a simple concept that can be demonstrated through an example you’ve most likely experienced. Assume you are ready to purchase more coconut oil as a raw material for production. The supplier offers a price of $13.30 for 7 lbs., and $67 for 50 lbs. While purchasing 7 lbs. will cost you $1.90 per lb. (13.30 / 7 = 1.90), purchasing 50 lbs. will cost you $1.34 per lb. (67 / 50 = 1.34) Thus, the supplier is passing on part of his cost-advantage of pouring a larger amount of coconut oil into a larger container (50 lb. pail), as opposed to having to break it down into smaller, 7-lb. containers, which takes more time and resources on the part of the supplier. As you can see from this example, when you raise your economies of scale, you are helping raise the economies of scale for your business partners as well.

Keeping with the scenario above, the economies of scale in your purchasing decision trickles down to your company’s ability to set its prices. If you purchased only 7 lbs. of coconut oil, your production cost will be higher than if you purchased 50 lbs. If your soap recipe includes four or more oils, and you purchased only 7 lbs. of each, you can quickly surmise how much higher the production cost of your bars will be compared to choosing higher quantities at lower prices. And with higher production costs, you must charge higher prices to cover all other operating expenses and earn a profit.

Understand that it is, of course, a good thing to charge higher prices, but only to a point. If a soap and skin care company must charge higher prices because their production costs are extremely high without devoting more resources to branding, marketing, labor and a host of other expenses, the company will end up pricing its products outside the range of affordability. Or, they might end up doing the opposite, which is what I see most often in our industry. Because they want their products to be affordable, no matter how high their production costs may be (often they don’t actually know their costs), they price products too low, which results in a thin (or, usually negative) margin that cannot endure the cost of labor and all other expenses. Often this becomes a pattern in which the owner repeatedly says, “someday I’ll be able to pay myself!” And that someday rarely comes, as every time revenue is earned, it almost immediately must be spent on costly raw materials and all other operating expenses. This can be avoided by developing a budget (plan) in which higher quantities of bulk raw materials are purchased.

Economies of scale may also reduce variable costs per unit because of operational efficiencies (we will explore variable costs later). Again, keeping with the scenario above, let’s look at a company’s economies of scale from an operational perspective. If the size of a soap company’s mold (or molds) is small, only small amounts of product can be produced. In contrast, if the size of the mold (or molds) is large, large amounts of product can be produced. And here is the rub. The reality is, in the world of soapmaking, the time it takes to make 30 bars of soap at one time compared to the time it takes to make 120 bars of soap at one time is not very different. Once a company has all its operational systems and proper equipment in place, time input either decreases or stays the same while production output increases, thus achieving higher economies of scale.

4 Keys to Increasing Economies of Scale

Lower Input Costs

An input cost is the cost of items such as labor and raw materials used in production. Regarding raw materials, when a soap and skin care company buys their inputs in bulk—from packaging, containers and raw materials to printed labels—it will take advantage of significant volume discounts. In turn, the different suppliers who sell the packaging, containers, raw materials and labels will also be achieving higher economies of scale by lowering their input costs through purchasing their volumes in even larger bulk quantities, guaranteeing a mutual partnership of low prices for both parties over time.

Purchasing in as large a quantity as possible from their suppliers, soap and skin care companies are aiding in the pricing reliability of their suppliers, which is a symbiotic business relationship.

With a soap and skin care business, the obvious components that come to mind are raw materials in the form of base oils, butters, fragrances, additives and caustic. As explained above, it is simple to comprehend how the ability to purchase these materials can significantly decrease overall production costs.

But what most startup businesses in our industry fail to consider is the true cost of labeling when printing from home.

If a startup soap and skin care company is currently printing labels from home, the cost associated with it can be incredibly high, both in terms of the financial investment, as well as the time investment (getting on the computer, printing the labels, either cutting the labels or procuring the sticker from the printed sheet, applying the label to the product, etc.). Many owners of soap and skin care companies that I coach will tell me that they cannot afford to purchase packaging/labels in bulk, or have professional companies print their sticker labels for them. I understand this dilemma as I’ve experienced it myself. But while it may seem like a large upfront investment, if one does invest in a professional packaging scenario, the time it takes to then apply the new packaging can be reduced dramatically, not to mention look much better. In almost every case I’ve seen, the time (labor) is reduced so much so that the overall cost of production is then notably reduced. Broadly speaking, the only way one could argue this point is if he/she didn’t consider time (labor) as part of their overall production cost in the first place, which is an absolute recipe for disaster.

Just starting out, my Mom used to wrap every bar of soap by hand with thin, feathery gingham paper. Once that was done, we would wrap a self-printed, cigar-band style label over the gingham that displayed all our pertinent information and logo. I didn’t have the dexterity or the patience for this. I was fast at everything else, but the packaging held me up, and it wasn’t fair to Mom to have to wrap all the soaps herself. The more we made and sold, the bigger a problem this became.

So, we eventually invested in a shrink-wrap system. After getting a system in place for its use, our production rate soared in comparison to hand-wrapping each bar. We didn’t lose out on the overall look, as we kept the same self-printed, cigar-band style labels that were placed over the shrink-wrap, just like they were placed over the old gingham paper, which now allowed for the soap to be seen, which was also a great benefit. Obtaining the shrink-wrap system was like going from an old, broken-down jalopy to a brand-new race car.

But the shrink-wrap wasn’t without its flaws. The wrap eventually became loose against the bars, often making the product look a bit ragged over time. Plus, I had a lot of frustrating do-overs when I would heat the wrap just a bit too long, causing it to tear. I very much appreciated the system, but our production and sales kept going up due to investing in larger molds and better equipment. Furthermore, we were printing our cigar-band style labels on an inkjet printer. Though I had them all nicely organized in Microsoft Word documents, I still had to head into the office room, turn on the computer, wait for Word to open, pull up the file, make sure the printer had ink, make sure we had the correct paper, and then click print. Our printer was slow. There was a sluggish, droning cadence of vert-vert-chuck, vert-vert chuck. With every chuck sound, a quarter-inch of printed paper was birthed from the printer. This took so much time and aching tolerance. I hated it.

Thus, we knew we needed to change yet again. This time we thought everything through from beginning to end, and decided that the best-looking option, which was also the quickest and least labor-intensive, was a box. The boxes were a large investment, but it reduced so many aspects of time and money that it was hard to fathom how we were doing things before. If the shrink-wrap system was a brand-new race car, our professionally printed soap box was a rocket ship.

Invest in Nontangible Input Costs

Some input costs are what I call “nontangible.” They are processes, programs and/or learned methods that develop a business owner’s overall acumen, confidence and even self-esteem. These cost inputs, such as business coaching, branding consultation, website design, research and development can be expensive, but because of the possibility of increased efficiency with these inputs, they will often lead to a decrease in the average cost of production and selling over time. This eCourse you have purchased and are reading now is in fact a nontangible cost input.

If the owner of a soap and skin care company chooses to spend money on business coaching (nontangible input cost), with a goal of ultimately streamlining her company by what she learns during coaching, she would simply have to increase the number of products she produces and sells to cover the initial investment made into the coaching. And if the owner truly knows the cost of production, along with a solid pricing structure, this can be planned and budgeted for with great ease.

Unfortunately, these types of nontangible input costs are recurrently the least-utilized input costs in our cottage industry, which is why so many crafters never make it to the next level of business achievement. Though you are different, as you are reading this, the reality is that most startups do not realize the importance of what I consider to be the three biggest advantages to the startup phase of the soap and skin care industry: 1) coaching, 2) branding consultation (or at the very least, significant investments of a company’s own time and energy into researching the subject), and 3) website design.

There came a time in my life and growing business that I reached stagnation. I wasn’t tired of the business, but I just felt stuck in doing the same things. I was doing the same thing every day yet expecting different results. I wasn’t putting any more money in my pocket even though I was working harder. I felt like I hit a ceiling regarding the number of wholesale accounts we could attain. To be completely honest, I wasn’t very happy at home. I needed to mix things up. Most importantly, I was vague in my vision, my goals.

My life completely changed after coaching and I created goal after goal after goal, all which eventually led to a brick-and-mortar storefront, nationally-franchised wholesale accounts and a shared sense of belonging with our community. I would not be the person I am today without my coach. (Thank you, Lisa). My return on the investment into coaching was far beyond worth it. And even though that was years ago, I still benefit daily from the lessons, advice and encouragement I attained.

My advice is to keep your business money in the bank for as long as you can, resisting the temptation to purchase fun and creative raw materials, and instead invest in intellectual property that will drive your business forward. These nontangible input costs are always worth the investment.

Specialized Input Costs

As production increases, a company can employ the use of specialized equipment resulting in greater efficiency. If the owner of a soap and skin care company chooses to spend money on larger molds, enhanced tools and streamlined packaging, she would simply increase the number of products she produces and sells to cover the investment made into the equipment, eventually reaching higher economies of scale over time. And if the owner truly knows the cost of production, along with a solid pricing structure, this can be planned and budgeted for with great ease.

When my company went from 12-lb. batches to 40-lb. batches, we made a serious leap in terms of economies of scale. I had much more time to devote to sales and could sell more units to current and prospective customers due to our increased production rate. I could make large quantities once or twice a week and then spend the rest of my time marketing and selling. Eventually, after achieving more and more sales, I knew that I needed to devote more of my time back into production or hire someone to help. As my time was wearing thin between making and selling, I pivoted back to spending most of my time in production (this time on a much larger scale) and then hired an independent sales rep to do my sales for me.

We were now producing roughly 2,000 bars per week, most of which were dedicated to wholesale accounts. And all of this was spurred by investing in larger molds and enhanced tools. This is not to discount the amount of work it took to make sales, as you can’t just simply purchase better equipment and automatically expect to sell more. But you will eventually reach a ceiling on what you can produce if your molds and equipment do not improve and increase. If there is a ceiling on how much your company can produce, there is an obvious ceiling on how much in sales your company can earn.

Techniques and Organizational Inputs

Eventually, with a larger scale of production, a soap and skin care company may also apply better organizational skills, such as a clear-cut chain of command, while improving its techniques for production and distribution (selling). For example, if a soap and skin care company has a brick and mortar storefront with employees, each store employee has uniquely designated tasks for each session of time at the workplace. Meanwhile, an independent sales rep might be out in the field, prospecting designated retail outlets to bring in more accounts. Everyone in the company has instructions and guidelines to follow, with each instruction and guideline ultimately aimed to move the company forward.

This can also be accomplished on the family/peer level. Many of us have a support system at home, from our spouses, siblings and children to our friends. Often, this support system can be invaluable to our progress, but only if they know exactly how to help. The chain of command applies to them as well. As the business owner, you cannot assume anything. Each task must be broken down into very manageable assignments with crystal clear instructions.

When I was tasked with creating to-do lists and expectations for my employees, I would create for them a three-ring binder. Each binder contained a calendar with their work schedules, time off, inspirational quotes and a sheet to showcase when they clocked in and out. But most importantly, there was a procedure list of everything that needed to be accomplished on any given day. And that procedure list was so simple and clear that my 7-year-old niece could run my shop by following it. This may sound over the top, but when it comes to asking for help, you must walk through every little step. If there are people in your life that are truly willing to help, you can do this same thing for them, even if they aren’t a formal employee.

Always remember, no one is going to care as much about your business as you. In my experience, it has become harder and harder to find suitable help, especially those who care and take initiative. Because of this, most people must have very clear instructions, as most will refrain from taking positive initiative. If you can create clear instructions for all those willing to help you and your business, your economies of scale will ultimately rise because of these organizational inputs.

Leave A Comment