This is day seven in my 30 day blogging challenge. My goal this month is to post one recipe every day. You can see day one here, day two here, day three here, four here, five here and day six here.

These recipes feature natural colorants and additives and are scented using natural essential oil blends. They will all fit into a 10″ silicone loaf mold (affiliate link http://www.brambleberry.com/10-Silicone-Loaf-Mold–P5199.aspx?bb=5) from Bramble Berry. So let’s get started!

Featured Ingredients:

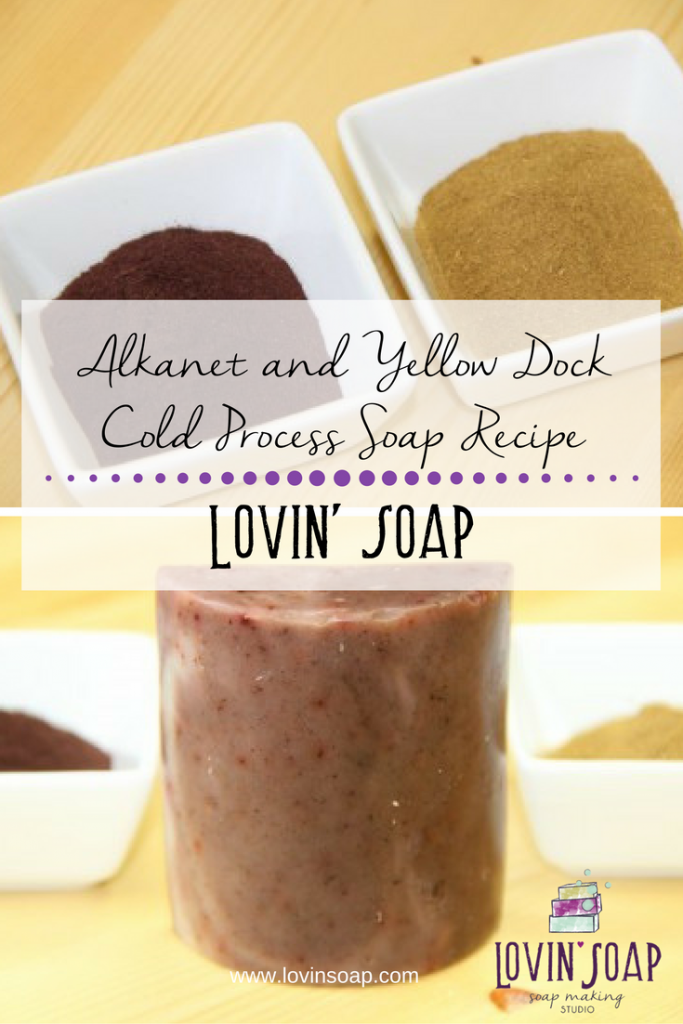

Alkanet Root Powder (below left) – Alkanet has traditionally been used as a natural plant-based dye for centuries. Depending on the pH of your soap and your alkanet crop (as batches vary), it will impart a purple to blue hue. Using little seems to give more of a grey/blue hue and using a lot will give you a dark purple. It can be scratchy so I like to toss mine in the liquid oils the day before to soften. You can also infuse oil and strain to remove the scratchy bits.

Yellow Dock Root Powder (below right) – You would think that yellow dock root would turn your soap yellow, right? Wrong! It actually turns a pink/red color in soap because of the pH. Using a lot will give your soap a crimson red color. I love using yellow dock as a natural colorant. Yellow dock root can also be applied as a poultice for minor wounds.

Alkanet and Yellow Dock Soap Recipe

Coconut oil – 12 oz.

Shea butter – 2 oz.

Olive oil – 10 oz.

Rice bran oil – 4 oz.

Castor oil – 2 oz.

Jojoba oil – 2 oz.

Lye – 4.4 oz.

Water – 9 oz.

Additives:

Alkanet Root Powder – 2 teaspoon

Yellow Dock Root Powder – 1 teaspoon

Essential Oil Blend:

Lavender Essential Oil – 40 grams

Anise Essential Oil – 20 grams

(I LOVE this essential oil blend. Try it!)

Basic Soapmaking Process:

New to soapmaking? Visit our basic tutorial here.

Step 1 – Wearing safety gear, weigh out the lye and water into two separate containers.

Step 2 – Pour the lye into the water while stirring. Place in a safe place and let cool while you prepare the oils.

Step 3 – Weigh out the hard oils/butters and melt.

Step 4 – Weigh the liquid oils into the melted oils/butters. This helps cool the oils down.

Step 5 – Add essential oils and additives to the melted oils. Stick-blend to get rid of clumps if any occur.

Step 6 – Once both the lye solution and oils have cooled to under 100° F, add the lye solution to the oils and mix to trace. Be sure to wear goggles and gloves!

Step 7 – Pour the soap into your mold.

Step 8 – Unmold, cut and cure your soap for at least four weeks.

Happy Soaping!

Amanda Gail