Mad Micas is included in the swatch gallery of my eBook, How to Color Soap. I fell in LOVE with their mica. They have an awesome lineup of colors, with equally awesome names. If you’re not familiar with their company, check it out here.

This tutorial uses four colors, Black Oyster, Silverfin Blue, Vanna White and Tahitian Teal. Want to see more Mad Oils mica put to use? Check out this tutorial.

This soap uses a simple funnel swirl soap design. I first saw this design when Corrie with Lomond Soap posted it on her blog (no longer available) several years ago. It is a staple among soapmakers these day. You simply color your soap different colors and pour, rotating colors, through a funnel to create an extraordinary design. If you’re soap-swirl challenged, or new to soapmaking, this is a great design to try!

Funnel Swirl Soap Design Recipe

Coconut Oil – 10 oz.

Shea Butter – 2 oz.

Olive Oil – 14 oz.

Sweet Almond Oil – 2 oz.

Rice Bran Oil – 4 oz.

Sodium Hydroxide – 4.5 oz.

Distilled Water – 9 oz.

Vanna White Mica (Mad Oils) – 3 teaspoons

Silverfin Blue Mica (Mad Oils) – 1/2 teaspoon

Black Oyster Mica (Mad Oils) – 1/2 teaspoon

Tahitian Teal Mica (Mad Oils) – 1/2 teaspoon

Slow-moving Fragrance or Essential Oil – 1.5-2 oz. (I used 1 oz. lavender essential oil and 1 oz. litsea essential oil.)

Mold: 3″ PVC Pipe – cut to 9″ tall

Safety Warning: This recipe is for soapmakers who have a basic knowledge of the soapmaking process and know the correct safety procedures to use when handling lye. If you are new to soapmaking, be sure to download our free guide, How to Make Cold Process Soap! Gear up in your gloves and your safety glasses.

Step 1: Create a lye solution. Weigh the water and lye into two separate containers. Slowly pour the sodium hydroxide into the water while stirring. Stir until completely dissolved and set aside to cool.

Step 2: Prepare the base oils. First, weigh any solid oils and butters into a container and melt. You can melt using the microwave or low heat on a burner. Next, weigh each liquid oil into the melted oils. The liquid oils will cool down the melted oils and leave you with a base oil mixture that is about at the correct temperature to make soap. It might still need to cool down a bit.

Step 3: Weigh your slow-moving essential oil or fragrance oil into a glass or stainless steel container and add to your base oil.

Step 4: Prepare your mold. If you need to line your mold, line it.

Step 5: Check the temperatures. You should now have a container containing liquid base oils and a container containing lye solution. Take the temperatures using an infra-red temperature gun. Be sure to stir each mixture before taking the temp. You want your temperatures to be between 80-100 degrees F.

Step 6: Once you have reached desired temperatures, pour the lye solution into the oil mixture and mix to emulsion.

Step 7 – Divide your soap out into four containers. You can leave soap in the main container for white. Add mica to each container and stickblend quickly to mix.

Step 8 – Rotating colors, pour each color through a funnel. As the soap enters the mold it will push out the prior poured soap into rings. Pour a lot for thicker rings, pour a little for thinner rings. Experiment with different pours.

Step 9 – Let your soap sit overnight to saponify. Unmold after 24 hours.

To unmold from PVC, it helps to put your mold into the freezer. Remove from the freezer and drop it onto one end (on concrete) to help jar the soap loose. Push out.

Happy Soapmaking! And Happy New Year!

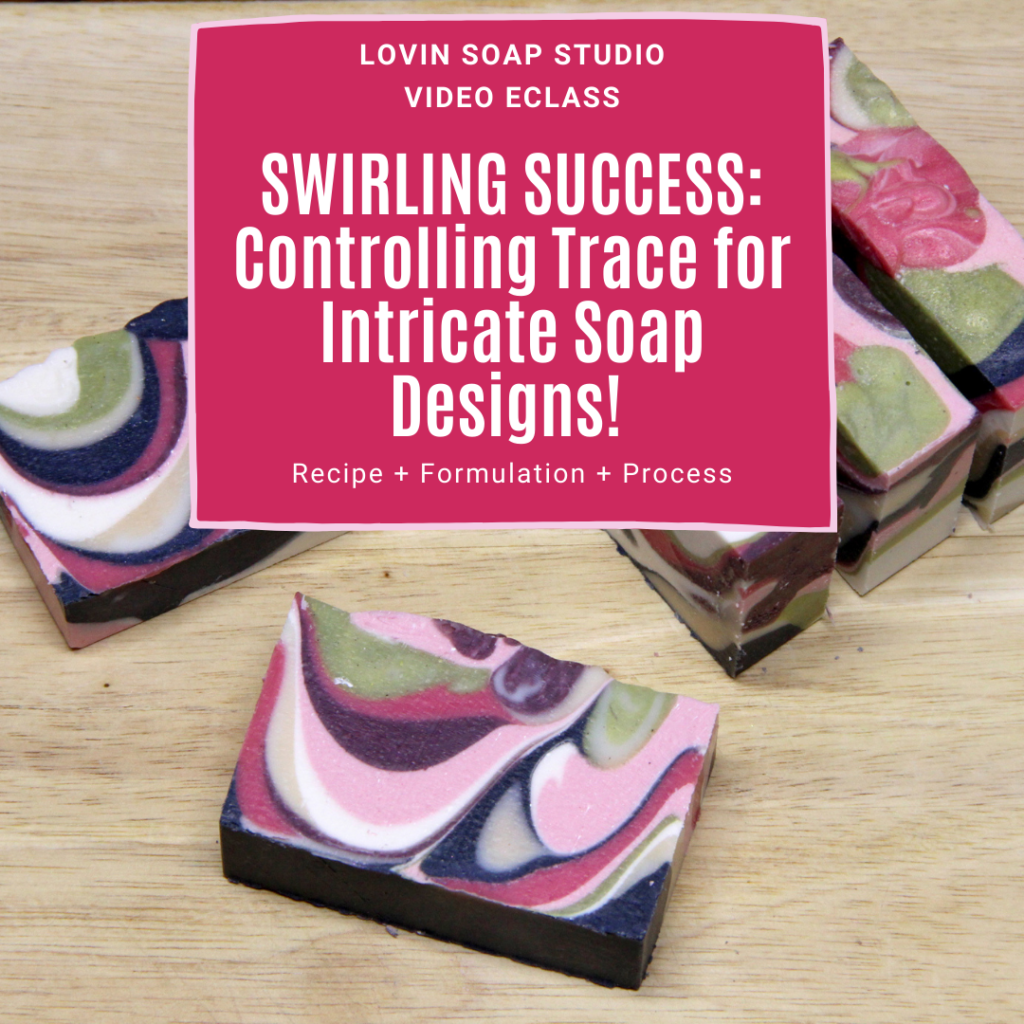

Grab our new eCourse, Swirling Success!

Learn to control trace, so it doesn’t control you!

This detailed video training explores the difference between emulsion and trace, so you know when to stop mixing your soap, allowing enough time to color and execute intricate designs. You’ll leave the eClass with a greater understanding of how water/liquid, temperatures, base oils, fragrance oils, essential oils and additives all affect the movement of your soap to trace.

?

Pretty

I found Mad Oils when they were a pretty new company and I too fell in LOVE with their Mica’s.. I was new to soaping so new I hadn’t even made soap but I was afraid that everyone else would find them so I ordered a ton of the colors and let me tell you they are gorgeous..My goal was to own every color they had…I also ordered it in the 3 or 4 oz (I can’t remember now) The owners are wonderful and answered all my questions.. You can’ t go wrong with them ~I just don’t have any of the browns..I bought so many and then had to buy EVERYTHING to make soap so it took me awhile..I got sick this past yr and haven’t been able to soap or to use my beautiful mica’s but I am hoping since spring is going to get here eventually (I live where it is still Snowing and it is April) but in 2 wks I should be able to start..Their pinks are GORGEOUS with the Turquoise and Blues…I LOVE them so I had to write…I just saw another Victoria “above my comment” say what I said…but in a much shorter sentence.lol What a small world. .Yep they are beautiful…

Hi! I follow you from Guatemala… we have a dumpling store and produce a lot of used cooking oil. Do you have ano specific recipe to use this oil and help our environment? (‘Cause the one I have didn’t work) ?

Best wishes…

I absolutely love that design! Those plastic pour containers really make it easier to get that perfect funnel swirl look. =)

I just recently purchased Tahitian Teal and think it’s gorgeous! I need a good black mica, so I think I’ll be trying out that Black Oyster. Thanks!

I LOVE Mad Oils Products…In fact I went so crazy over them, I bought them first before I even learned how to make soap…lol