This is probably one of my favorites that I have made! I LOVE the color scheme and the way the funnel pour came out!

Here are some more fun designs made in PVC pipes.

- Pumpkin Puree + Pumpkin Beer Soap

- Funnel Pour Soap Design with Mad Oils Mica

- Rimmed Soap Tutorial – 80’s Glam Edition

- Millefiori Soap Design (Multiple Funnel Pour Design)

- Charcoal Facial Bar with Mango, Avocado and Babassu

And if you need help unmolding your soap from PVC, check out this post.

Let’s make this soap!

(Disclosure: Some of the links below are affiliate links, meaning, at no additional cost to you, I will earn a commission if you click through and make a purchase.)

I used 3″ wide PVC pipe that I cut to 9″ tall.

Funnel Pour in PVC Pipe Soap Design

Basic Body Bar – More Moisture from Lovin Soap Studio Recipe eBook (Grab your copy for 50 cold process soap recipes + 64 essential oils blends!)

Base Oils

- Coconut Oil (76 degree) – 270 grams (30%)

- Shea Butter – 90 grams (10%)

- Olive Oil – 342 grams (38%)

- Avocado Oil – 72 grams (8%)

- Rice Bran Oil – 126 grams (14%)

Lye Solution

- Sodium Hydroxide – 126 grams (5% superfat)

- Water – 252 grams (1:2, lye:water ratio)

Scent

Use your favorite slow-moving fragrance or essential oil blend. I simply used a blend of lavender and litsea essential oils. If you’re looking for a good place to get essential oils, I HIGHLY recommend Appalachian Valley Natural Products. I love their products and their shipping is super fast!

- Lavender Essential Oil – 15 grams

- Litsea Essential Oil – 15 grams

Colors

- Honey Do (Muddy Micas)

- Bee in my Bonnet (Muddy Micas)

- Bleu (Muddy Micas)

- White Mica

- Cosmetic Charcoal

Let’s make soap! If you are new to soapmaking, be sure to download our free guide, How to Make Cold Process Soap! Gear up in your gloves and your safety glasses.

Step 1: Create a lye solution. Weigh the water and lye into two separate containers. Slowly pour the sodium hydroxide into the water while stirring. Stir until completely dissolved and set aside to cool.

Step 2: Prepare the base oils. First, weigh any solid oils and butters into a container and melt. You can melt using the microwave or low heat on a burner. Next, weigh each liquid oil into the melted oils. The liquid oils will cool down the melted oils and leave you with a base oil mixture that is about at the correct temperature to make soap. It might still need to cool down a bit.

Step 3: Weigh your slow-moving essential oil or fragrance oil into a glass or stainless steel container and add to your base oil.

Step 4: Prepare your mold. If you need to line your mold, line it.

Step 5: Check the temperatures. You should now have a container containing liquid base oils and a container containing lye solution. Take the temperatures using an infra-red temperature gun. Be sure to stir each mixture before taking the temp. You want your temperatures to be between 80-100 degrees F.

Step 6: Once you have reached desired temperatures, pour the lye solution into the oil mixture and mix to emulsion.

Step 7: Once emulsified, divide your soap to color. I divided mine into 8 cups.

Step 8: Add colorants to each cup and mix well using a mini-mixer. I mixed some of my colorants to create a more diverse color scheme.

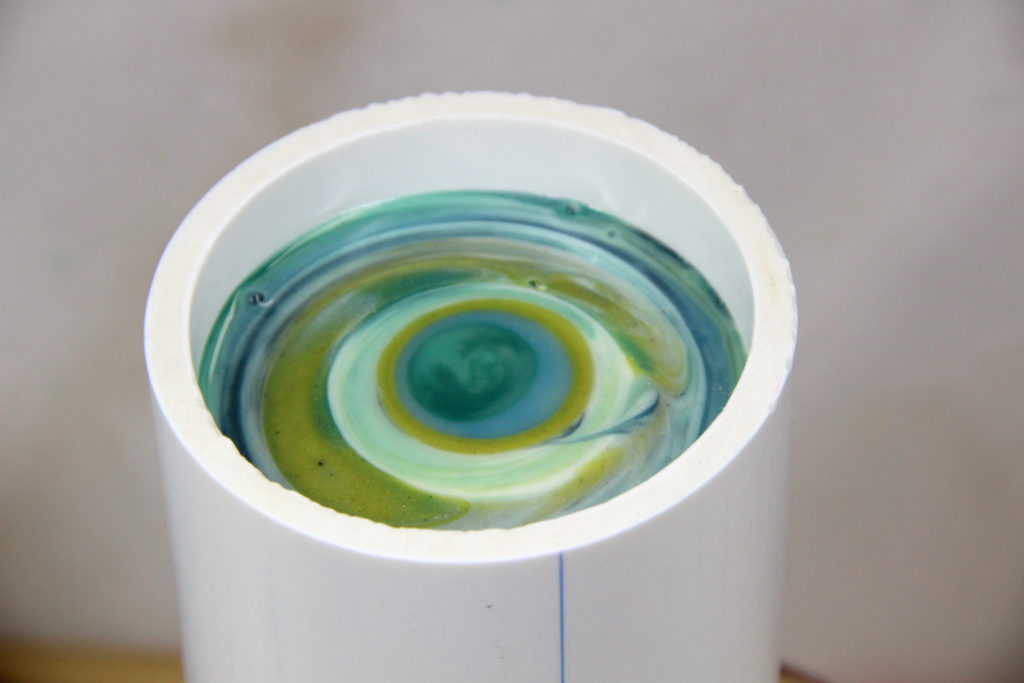

Place a funnel in your PVC pipe to pour your colors into. You don’t HAVE to have a funnel, but it does help keep the soap pouring in one place without moving around. Make sure the bottom of the mold is secure! You don’t want soap coming through. You can purchase PVC caps, or you can secure with plastic wrap and rubber bands. I always place my mold inside of another container in case it leaks!

Step 9: Rotating through each color at least 6-10 times, pour each cup of colored soap into the funnel that is sitting at the opening of the mold. The funnel helps the soap to fall into the center of the mold. Small pours will create thin rings and heavy pours will create thicker rings. When you get closer to the top of the PVC mold, you might have to lift the funnel out and hold it with your other hand as you pour. The soap might look like it is muddying up as you pour, but when you go to cut you’ll find the beautiful pattern.

Step 12: Allow your soap to saponify and harden for at least 24 hours. After 24 hours, you can unmold and cut. Cure your soap for 4-6 weeks.

Thanks for reading!

Grab our new eCourse, Swirling Success!

Learn to control trace, so it doesn’t control you!

This detailed video training explores the difference between emulsion and trace, so you know when to stop mixing your soap, allowing enough time to color and execute intricate designs. You’ll leave the eClass with a greater understanding of how water/liquid, temperatures, base oils, fragrance oils, essential oils and additives all affect the movement of your soap to trace.

An absolutely gorgeous soap! I love your color combinations!

How did you “un-mold” your pvc pipe soap? Did you have to cut the pvc?

Amanda has a video –

https://www.google.com/search?client=firefox-b-1-d&q=+to+unmold+soap+from+PVC+Pipe#kpvalbx=_Zfv5YeXvO42ekPIP4qewuAE20

Homemade soap is very cool, especially when you make it in large quantities, which makes it possible to even sell it, all the more if you do it as beautifully as you did in your post. As forms, you can also use all different baths, just look at home, it is also very cool.

in general, I think that all hygiene products should be done at home, since this way full control over what and how much is added there

Looks great! Can’t wait to try it! =)

Looks great! Can’t wait to try it!

Looks like fun and I’m going to try it. What kind of cups are you using? Just regular disposable ones?

Thanks for all the great info!